Compression Damping Cycle

|

1. Compression

cycle

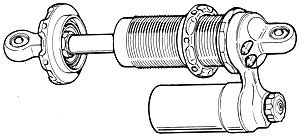

To show you what is happening in an Íhlins TT44 we use the damper

with the 4-way option. The principle illustrated here is the

same for both the basic 3- and the optional 4-way configuration.

Just disregard the poppet valve in the piston shaft and you

will understand how the 3-way configuration works! |

The 3-way configuration stands

for the basic TT44 damper with three external adjusters.

For a start we assume that the adjustable reservoir compression

bleed valve, fig 1E, is fully open. In this case, the

pressure on the compression side of the piston, fig 1G,

will remain almost constant and the same as the gas pressure

during the whole stroke, though some small change of the pressure

will occur because of the change of gas volume caused by shaft

displacement.

As long as the reservoir compression bleed valve is set to fully

open, only the pressure drop on the rebound side of the main

piston, fig 1H, causes the oil to move from the compression

side to the rebound side of the piston.

This means that the initial nitrogen pressure in the reservoir

has to be high enough to handle the compression forces. If the

pressure is too low there is a risk of dumping more oil than

the shaft displaces into the reservoir and the rebound chamber

will not be completely full.

When track conditions cause the vehicle suspension to move,

the damper piston will attempt to move through the damper oil.

In order for the piston to move, oil must flow from one side

of the main piston to the other.

In the initial part of a compression stroke, when the velocity

of the piston is low, the oil flow bypasses the main piston

by travelling through the adjustable low-speed compression bleed

valve, fig 1A, the compression check valve, fig 1B,

and then flows between the two tubes, fig 1C. The oil

re-enters the main tube on rebound side through a port near

the end cap.

As the piston velocity increases the pressure drop across the

main piston will increase. The compression shim stack, fig

1D, depending on the combination of shims, opens at a certain

pressure, providing a direct pathway for the oil, allowing it

to pass through the stack to the other side of the piston.

Observe that it is the pressure drop on the rebound side of

the piston that causes this, not the increase in pressure on

the compression side. Depending on the shim stack, the opening

will be something from abrupt to gradual. A small amount of

oil will always flow through the bleed valve as long as the

piston is moving.

Note: In practice many strokes never reach a velocity

high enough to cause enough pressure drop across the main piston

necessary to cause the shims to open.

During the compression stroke, the oil displaced by the volume

of the piston shaft as it enters the main body is forced into

the reservoir. This causes a small increase in system pressure

due to the piston shaft volume displacement moving the floating

piston and therefore compressing the nitrogen.

In the passage connecting the main body and the reservoir, there

is another compression valve system (one bleed valve in parallel

with a shim stack) similar to the system found in the main body.

By closing off the compression reservoir bleed valve, fig

1E, the reservoir valve system contributes to the total

compression damping.

The reservoir compression bleed valve regulates the flow at

low piston velocities. At higher piston velocities, the reservoir

compression shim stack, fig 1F, opens to provide a pressure

blow-off.

The pressure differential across the main piston will build

up quicker if there is some damping from the reservoir, because

there is not only a pressure drop on the rebound side of the

main piston, but also a pressure rise on the compression side.

Because of the restriction in the reservoir, the pressure in

the whole damper body will rise. This will reduce the risk of

cavitation.

4-way configuration

What has already been described here about the 3-way compression

cycle is still valid with the addition of the "4-way" option,

but now there is also a poppet valve in parallel with the compression

shim stack of the main piston.

The poppet valve is pushed against its seat by a preloaded coil

spring. The amount of preload can be externally adjusted. This

preload determines what pressure differential across the main

piston is necessary to make the poppet valve open.

The 4-way valve provides an additional pathway to the other

side of the piston. The new pathway goes through the centre

of the shaft, fig 1I, and then encounters the 4-way poppet

valve, fig 1J.

As the piston velocity increases the pressure drop across the

main piston rises. At some velocity the movement of the piston

creates a pressure drop across the main piston that equals the

pre-determined pressure required to open the valve. After passing

the valve the oil exits the cross-drilled holes, fig 1K,

in the shaft on the other side of the piston.

Depending on the combination of shim stack and poppet valve

preload, the 4-way valve can open before, at the same time or

after the main piston shim stack. This determines the character

of the damping curve. |

Rebound Damping Cycle

|

2. Rebound

cycle

Again, the principle illustrated here is the same for both the

basic 3- and the optional 4-way configuration. Just disregard

from the poppet valve in the piston shaft and you will understand

how the 3-way configuration works! |

The rebound damping cycle

is the same whether the damper is of 3- or 4-way type.

During the rebound stroke, the pressure of the rebound side

of the main piston is increasing, while the pressure of the

compression side is kept almost constant. This causes the oil

to move back across the piston. When the piston velocity is

low, oil initially will flow between the two tubes, fig 2A,

and arrive at the low-speed rebound bleed valve, fig 2B.

After the valve has metered the flow, the oil will open the

rebound check valve, fig 2C, and travel to the compression

side of the piston.

When the opening pressure of the main piston shim stack is reached,

oil will also pass through the stack, fig 2D.

To compensate for the displacement change caused by the shaft

leaving the body, a check valve in the reservoir, fig 2E,

will open so that oil can return to the compression side of

the piston freely. This will cause a small decrease in system

pressure due to the reduction of piston shaft volume displacement

moving the floating piston and therefore expanding the nitrogen.

4-way configuration

The poppet valve of the 4-way adjuster, fig 2J, has the

function of a check valve. It will seal against the valve seat

during the rebound stroke and therefore prevent oil from flowing

back through the shaft. The oil passage will become identical

to the standard 3-way type damper during the rebound stroke. |

| |

External Damper Adjustmets

|

Standard

external adjusters

- = soft. + = hard. |

Optional

high speed compression damping adjuster

- = soft. + = hard. |

The TT44-damper comes

standard as a 3-way externally adjustable damper with

an optional "4-way" adjuster. The adjusters are:

Low-speed compression damping adjuster (LSC)

Type of adjuster: Bleed adjuster.

Affect: The flow from the main piston during compression

strokes only.

Identification: Gold knob at the head of the cylinder

body.

Number of positions: Approximately 38

Low-speed rebound damping adjuster (LSR)

Type of adjuster: Bleed adjuster.

Affect: The flow from the main piston during rebound strokes

only.

Identification: Silver knob at the head of the cylinder

body.

Number of positions: Approximately 38.

Reservoir compression damping adjuster (RC)

Type of adjuster: Bleed adjuster.

Affect: The flow from the displacement of the shaft during

compression strokes only.

Identification: Black knob at the top of the reservoir.

Number of positions: Normally within 20-25. Depends on

the shim stack used.

Optional high-speed compression damping adjuster (HSC)

Type of adjuster: Poppet valve preload adjuster.

Affect: The flow from the main piston during compression

strokes only.

Identification: Gold wheel in the end eye.

Number of positions: Approximately 55. |

|

Modular Design

|

The TT44 is designed

for 2 1/4" I.D. springs, but there is also a version for 36

mm I.D. springs (1" I.D. springs can also be used), where the

spring platform is placed on the end cap of the cylinder body.

However after doing some modification, it is possible to fit

some 2" I.D. springs around the cylinder body. Normally the

teams do these modifications themselves.

Note: Reservoir attachment ring as well as the hose attachment

ring rotate and can be mounted at any angle on the cylinder

body.

It is also possible to have reservoir pointing away from shaft

by turning piggyback bracket upside down, if space restrictions

will prevent the conventional mounting. |

|